Light Truck Assembly Line

The truck assembly line is a complex manufacturing process that involves multiple stages to ensure efficient production and high-quality standards of the vehicles. Here are the main steps of a truck assembly line:

Chassis Assembly: The truck chassis is the foundation of the vehicle, including the assembly of the frame, suspension system, powertrain, and braking system.

Cab Assembly: This involves the assembly of the cab, including the installation of windows, doors, dashboard, and interior trim such as seats, carpets, and control panels.

Engine Assembly: The engine is installed onto the chassis and connected to the intake and exhaust systems, as well as the cooling system.

Final Vehicle Assembly: The combination of the chassis and cab, the assembly of the electrical system, the installation of tires and wheels, and the final inspection.

Performance Testing: Includes four-wheel alignment, brake testing, endurance testing, break-in testing, noise testing, and power tests.

Road Testing: Simulating real road conditions to test vehicle performance.

Final Inspection: Quality checks after all tests are completed to ensure the vehicle meets factory standards.

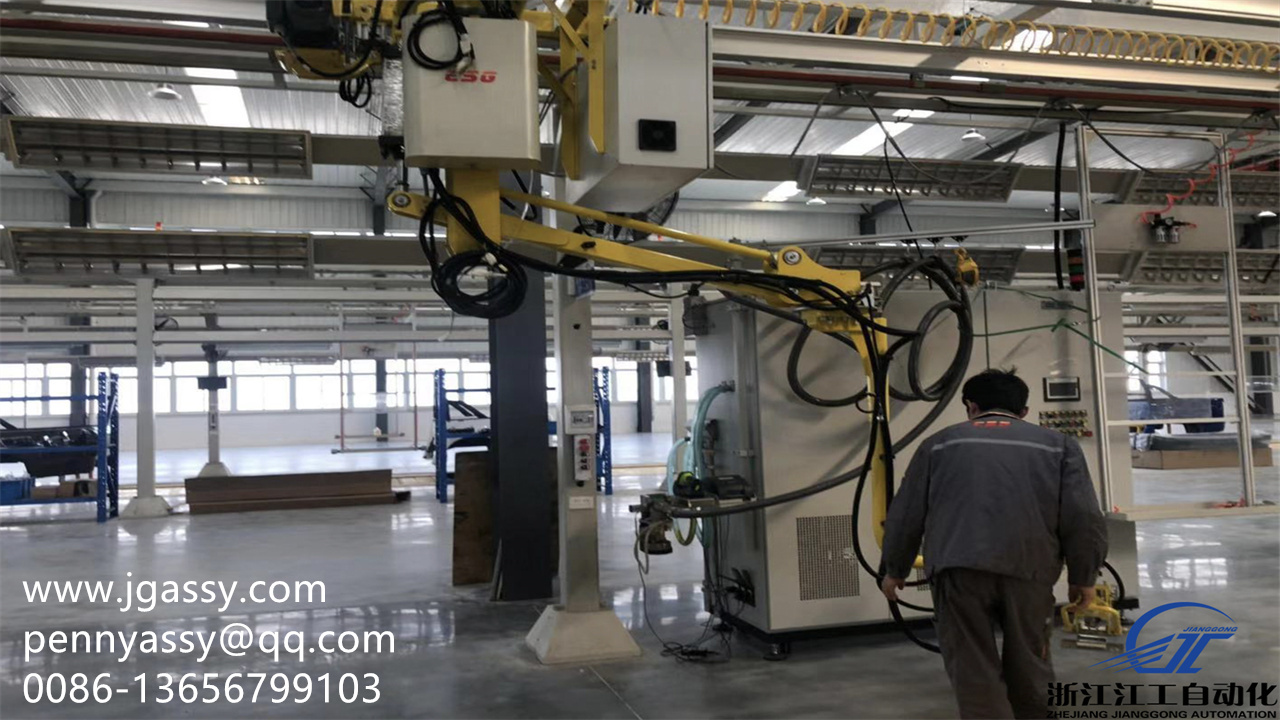

Automated Equipment: Automated conveyor systems, robotic welding, and automatic fastening tools are used to improve production efficiency and accuracy.

MES System: Monitors production progress, optimizes resource allocation, and enhances intelligent management levels.

The entire truck assembly line is a highly integrated and automated process that ensures vehicle performance and reliability through precise process design and advanced automated equipment.

- 2024-12-05

- 2024-12-04

- 2024-12-04

- 2024-12-04

- 2024-12-04

- 2024-12-04

- 2024-12-03

- 2024-12-03

- 2024-12-03

- 2024-12-03

- 2024-12-02

- 2024-12-02